Well,

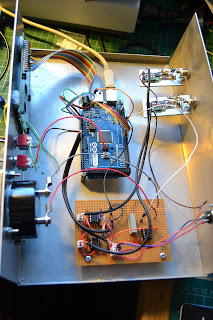

You may remember the musings from a while ago where I made the dBm meter for the shack:

http://g0mgx.blogspot.co.uk/2012/11/calibration-complete.html

I wasn't overly convinced of my calibration, the 'scope, spectrum analyser and this meter didn't align, especially at low power levels. There is always a risk that the old test equipment I have (the spectrum analyser) is well out of calibration, but I was curious. The calibrator that I made (Design courtesy of Mr Kopski, K3NHI) didn't quite look correct on the 'scope either - it was described as a square wave, but mine looked kind of triangular like this:

But it did look full of harmonics when viewed on the spectrum analyser:

So, I started by asking some suitably dumb questions on a forum or two, and ended up in a very educational and excellent email exchange with my new found chum Kerry who lives down under.

To cut a long story short, Kerry has some very accurate test kit (accurate read expensive!) and has kindly fed some known signals into an AD8307 RF front end (like the one in my power meter) and noted the voltage output by the device itself, here are the values:

So, I took these values and plotted them as a X-Y scatter plot in good old Excel, then added a trend line to each set of data and got the spreadsheet to include the equation on the graph:

Now, hopefully you will be able to see that using the equation on the graph, we can now calculate any dBm value that the meter should be displaying from the actual voltage on the device output (pin 4).

So, using my good faithful Avo signal generator and some of the attenuators I made earlier, plus the attenuator on the Avo itself, I have fed a load of different RF signals into the meter, read the voltage on pin 4 of the AD8307 and then used the equation to calculate the dBm value that the voltage represents:

Once this was complete (ignore the yellow above for now), I then used the lowest and nearest to 0dBm to calibrate the meter. The yellow values are the meter actual display readings once the calibration was complete.

My confidence is now very high in this homebrew instrument and I suspect it may become the most useful device yet.

So, feeding a -30dBm signal (as measured with the calibrated meter) into my Spectrum Analyser with the reference level (top line on the display) set to 0dBm, the fundamental 5MHz signal in this photo is shown -30dBm down from the 0dBm reference level i.e. they agree! Sorry about the wonky photo:

Here is the dBm meter with the Avo signal generator set at 0dBm and a -10dB attenuator (pad) in line with the feeder; 0.3dBm is really very close indeed:

Oh, and the suspect Kopski calibrator? That now reads 19.9dBm - can't be bad! It was the -50dBm version that I concocted myself that was highly suspect - it reads -39dBm!

I've started an Analogue equivalent of the meter, initially because this would only require a single calibration point, but now I have found a better way to calibrate the digital meter, the project is rather redundant. I'm rather pleased with the meter scale though:

And all this because I became suspicious of the readings I was seeing from the attenuators I created as part of this project:

http://g0mgx.blogspot.co.uk/2012/12/ddsing-once-more.html

Hey, Ho. Perhaps now I am happy with the dBm meter, I can progress that project? Unfortunately I've run out of holiday and have to go back to work. I suppose there's always next Christmas.

Fun though, egh?

You may remember the musings from a while ago where I made the dBm meter for the shack:

http://g0mgx.blogspot.co.uk/2012/11/calibration-complete.html

I wasn't overly convinced of my calibration, the 'scope, spectrum analyser and this meter didn't align, especially at low power levels. There is always a risk that the old test equipment I have (the spectrum analyser) is well out of calibration, but I was curious. The calibrator that I made (Design courtesy of Mr Kopski, K3NHI) didn't quite look correct on the 'scope either - it was described as a square wave, but mine looked kind of triangular like this:

But it did look full of harmonics when viewed on the spectrum analyser:

So, I started by asking some suitably dumb questions on a forum or two, and ended up in a very educational and excellent email exchange with my new found chum Kerry who lives down under.

To cut a long story short, Kerry has some very accurate test kit (accurate read expensive!) and has kindly fed some known signals into an AD8307 RF front end (like the one in my power meter) and noted the voltage output by the device itself, here are the values:

So, I took these values and plotted them as a X-Y scatter plot in good old Excel, then added a trend line to each set of data and got the spreadsheet to include the equation on the graph:

Now, hopefully you will be able to see that using the equation on the graph, we can now calculate any dBm value that the meter should be displaying from the actual voltage on the device output (pin 4).

So, using my good faithful Avo signal generator and some of the attenuators I made earlier, plus the attenuator on the Avo itself, I have fed a load of different RF signals into the meter, read the voltage on pin 4 of the AD8307 and then used the equation to calculate the dBm value that the voltage represents:

Once this was complete (ignore the yellow above for now), I then used the lowest and nearest to 0dBm to calibrate the meter. The yellow values are the meter actual display readings once the calibration was complete.

My confidence is now very high in this homebrew instrument and I suspect it may become the most useful device yet.

So, feeding a -30dBm signal (as measured with the calibrated meter) into my Spectrum Analyser with the reference level (top line on the display) set to 0dBm, the fundamental 5MHz signal in this photo is shown -30dBm down from the 0dBm reference level i.e. they agree! Sorry about the wonky photo:

Here is the dBm meter with the Avo signal generator set at 0dBm and a -10dB attenuator (pad) in line with the feeder; 0.3dBm is really very close indeed:

Oh, and the suspect Kopski calibrator? That now reads 19.9dBm - can't be bad! It was the -50dBm version that I concocted myself that was highly suspect - it reads -39dBm!

I've started an Analogue equivalent of the meter, initially because this would only require a single calibration point, but now I have found a better way to calibrate the digital meter, the project is rather redundant. I'm rather pleased with the meter scale though:

And all this because I became suspicious of the readings I was seeing from the attenuators I created as part of this project:

http://g0mgx.blogspot.co.uk/2012/12/ddsing-once-more.html

Hey, Ho. Perhaps now I am happy with the dBm meter, I can progress that project? Unfortunately I've run out of holiday and have to go back to work. I suppose there's always next Christmas.

Fun though, egh?